Unique Features Video

More Info

New Installations

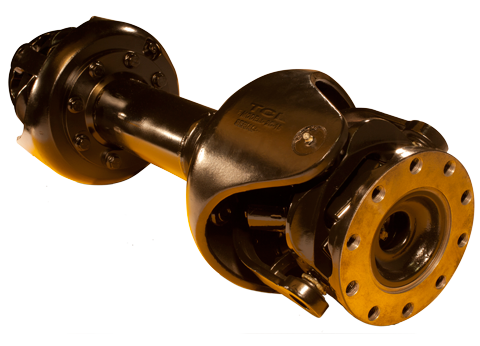

One of the worlds largest steel mills have chosen our TCAE-R-7 to operate on their rolling table.

One of the worlds largest steel mills have chosen our TCAE-R-7 to operate on their rolling table.

We have supplied 4 of the TCAE-R-7 couplings. It is operating on 85kW motor at 579RPM with Machine Service Factor 2 for heavy duty.

This will last over 3 years in operation without any maintenance or laser aligning and is truly a drop in solution.

Accreditations

Our approved ISO 9001 quality management system reflects our promise to deliver to you the best quality product and support for your specific driveline application.

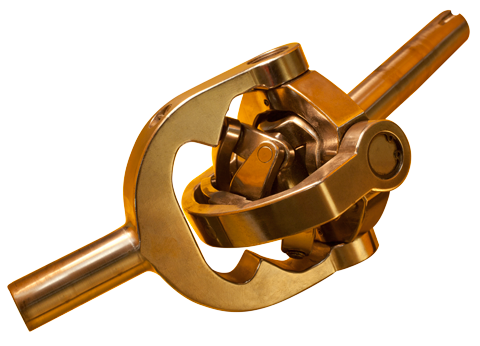

With the applications of couplings to special oil and gas installations Thompson Couplings Ltd can now offer ATEX approved (Atmospheric Explosive) couplings that couple motors and pumps or other equipment unique to explosive risk industries. Thompson Couplings is proud to be certified by American Shipping Bureau (ABS).

Our trained staff can also assist with the installation of couplings for compliance with the American Petroleum Institute API-671 and internationally ISO 10441:2007. The range of TCAE Alignment Eliminator couplings fulfil the requirements of the standard for flexible couplings for mechanical power transmission; this includes all types of industrial plants, being, Steel Mills, Aluminium Plants, High Acid Soft Drink Plants, Paper and Recycle Plants, marine, trucks mining, as well as those unique to the oil and natural gas industries and many more; based on our product design materials of construction, manufacturing quality and inspection and testing procedures.

Cost of Ownership

These losses ,when added together, appear in reporting as Down-Time, the most damaging contributor to profitability.